Ground test: Where lethality is designed

Part 3 - Ground Test: Where Lethality is Designed

Before an aircraft ever flies, before a weapon system is put through its paces in the open air, it meets reality in a quieter, more controlled setting: ground test. But don’t let the name fool you. This isn’t just about data collection. This is where design decisions live or die. Where digital theory becomes physical fact. And at the Air Force Test Center, ground test is where the digital thread starts to become anchored in reality.

Thanks to digital engineering and classical design methods, many design tradeoffs are made long before hardware exists. But once you move from simulation to the physical realm, you need data you can trust. That’s where ground test comes in. It’s the first opportunity to update the digital twin with data from the real system. That feedback loop and first handshake between model and machine is what turns a good design into a great one.

“Digital engineering only works if your models are anchored in truth,” said John Grigaliunas, AFTC Technical Advisor for Flight Test & Evaluation. “And that truth must come from test. Early and often.”

Not Just Test. Design in Disguise

At AFTC, ground testing isn’t just verification, it’s design in disguise. Whether it’s testing aero-propulsion at Arnold Engineering Development Complex, refining electronic warfare systems at the Benefield Anechoic Facility at Edwards, or validating weapons at the Guided W

In fact, calling it “test” is almost unfair. The facilities across AFTC’s enterprise don’t just confirm what works, they drive the design forward. Each location plays a unique, indispensable role:

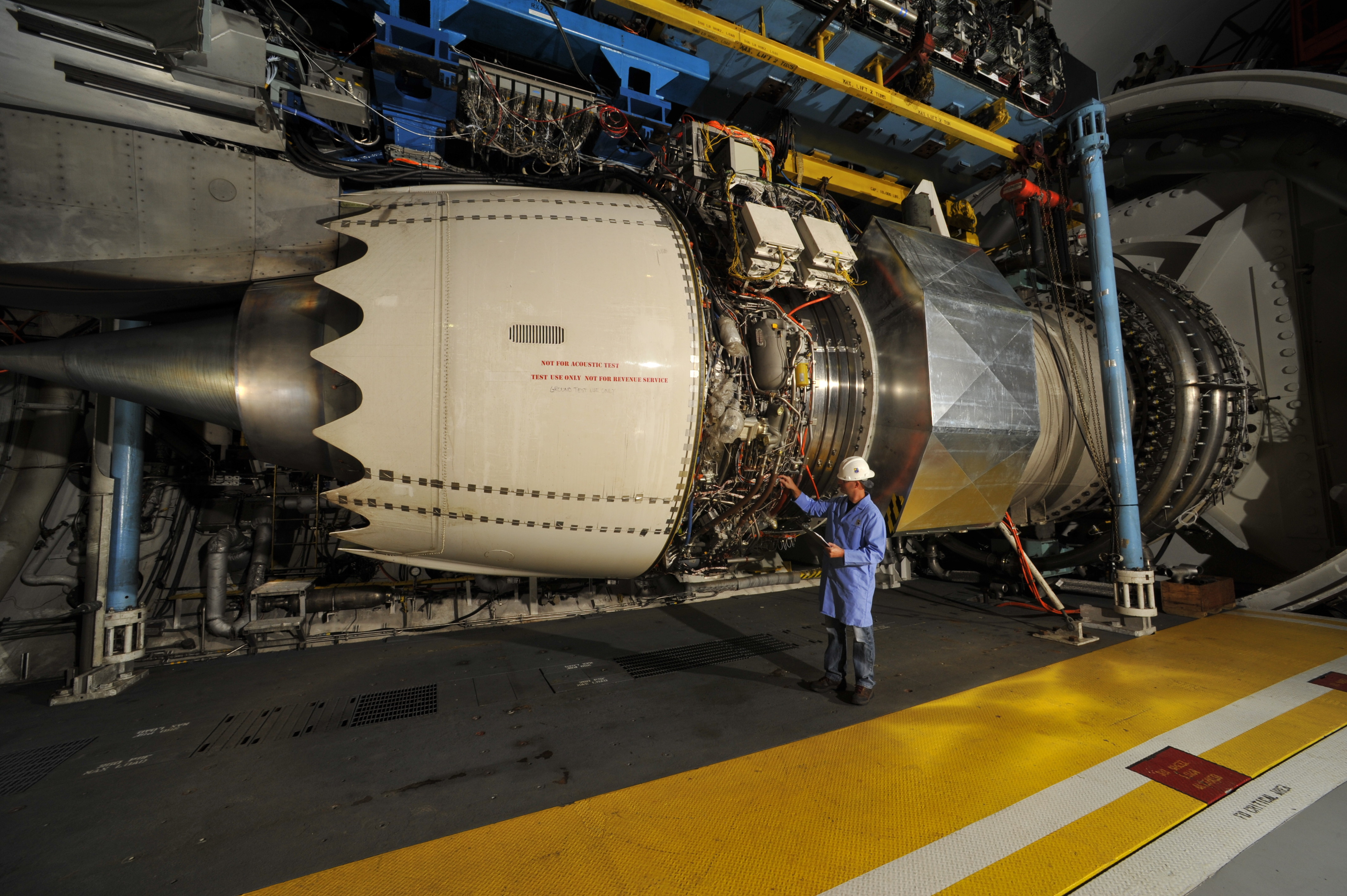

- At Arnold AFB, engineers push systems to their limits in high-temperature, high-speed environments using advanced wind tunnels and engine test cells. This aero-propulsion data is crucial for validating early-stage design assumptions.

- At Edwards AFB, facilities like the BAF provide a controlled RF environment to simulate and refine mission system survivability before they hit the open air.

- At Eglin AFB, the GWEF and other mission systems testbeds validate missile and munitions guidance systems, giving designers the data they need to iterate faster and more effectively.

With low measurement uncertainty, tight environmental control, and the ability to run around the clock, ground test environments offer a major advantage over flight test. Scalable repeatability.

Historically, the acquisition world followed a linear path: design, model, test, then evaluate. The digital thread blows that up. Now, the capability development process is more abstract. The same day a change is made to a model, a test article can be run in a lab, and the data fed back in.

But here’s the catch: many believe digital engineering means we can test less. That’s not always true. In some cases, to reduce uncertainty to an acceptable level, we may need to test more. The good news? Ground test lets us does that quickly and affordably. It’s fast, flexible, and functionally essential.

“The real magic of the digital thread is that it helps you understand where you need to concentrate your product development,” said Grigaliunas. “It’s not about doing less ’test’. It’s about doing smarter work.”

The Authoritative Source of Truth

In digital engineering, the gold standard is the digital twin, a virtual replica so accurate you can trust it to make design decisions. But a twin is only as good as the truth it’s built on. That truth comes from data, and that data starts with T&E.

“At AFTC, our vision is to operate as an Integrating Center, connecting the design, test, and delivery of war-winning capabilities, underpinned by a digital thread,” said Maj. Gen. Scott Cain, AFTC commander. “Ground test plays a foundational role in that vision. It’s where we first validate digital models with trusted data and shape designs before they ever leave the bench. Just as our strategic plan prioritizes capability development at the speed of need, our ground test teams provide the early insights that accelerate timelines, reduce risk, and deliver combat advantages to the warfighter.”

Digital engineering doesn’t replace test. It transforms it.

Up Next: Part 4 - Flight Test and Flag Exercises - Proving Lethality in the Real World